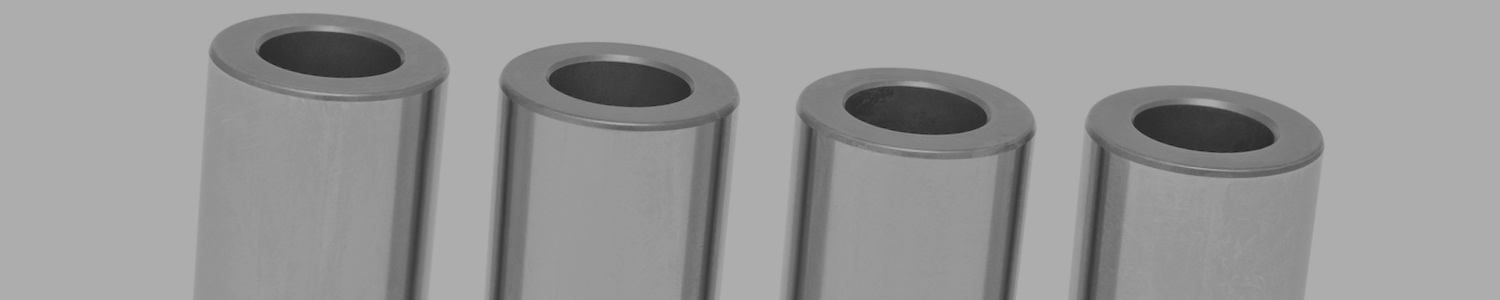

Piston Pins or Gudgeon Pins are used in all combustion engines and are arguably one of the most highly stressed components of an engine. To achieve the specification demanded by the industry, the pins are highly engineered and have come to be a speciality of Coker.

The piston pin or gudgeon pin is a hollow rod with a small diameter that is typically made of an alloy steel exhibiting high strength and hardness properties.The pins are manufactured to withstand very high temperatures whilst being small and light and crucially need to be able to withstand heavy loads and bending forces.

With many years experience of manufacturing piston pins for the motorsport market and various other industries, Coker have built up a wealth of experience and skill in this crucial area. If you would like to learn more about our Piston Pin manufacturing services or would like to discuss your precision engineering requirements with us. Call us on 44(0)1460 67162 or email us at pins@cokerengineering.com

Features of Piston Pin Manufacturing:

- Single source heat treatment supplier with dedicated nitriding furnaces

- Microfinished and Tribofinished diameters to 0.03Ra

- Honed bores to 0.3Ra

- DLC coating if required

- Roundness to 0.001 max

- Inspection laboratory

- MFD crack detection

- Micro hardness testing

- Prototype service available for small test runs through to production volumes.